Report the ad

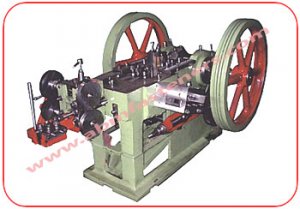

Rivet making plant - Delhi

Monday, 9 April, 2012

Item details

City:

Delhi

Offer type:

Sell

Item description

BLIND (POP) RIVET MAKING PLANT (High Speed)

a) Automatic High Speed Double Stroke Cold Heading Machines

b) Automatic Blind (Pop) Rivet Assembling Machines

c) Automatic Wire Nail Making Machines (For Blind / Pop Rivet)

DOUBLE STROKE COLD HEADING MACHINES (Automatic, High Speed)

FEATURES

These cold heading machines are fully automatic and easy to operate with little training, fitted with Solid Die to produce blank for Bolts, Screws, Rivets and other similar components. Cut off and knock out mechanism have safely devices that will stop any major accident if any abnormal function occurs in machines.

A positive knock out provision had been made on the 1st and 2nd punches to eliminate the possibility of parts sticking to these punches during the operations. The maximum parts of the machines are ground and all the Cames and Rollers from H.C.H.C. ( Hardened & Ground ).

On some extra charges machines will be equipped with Pneumatic Clutch & Automatic Centralized Lubrications systems which provides sufficient quantity lubricating to all bearing surface.

SPECIFICATION

Item Code No. Length Diameter Production

Per Minute Motor H.P.

ABM-FM-6540 12 mm - 20 mm 2.5 mm - 4 mm 70 - 80 Pcs. 2 H.P.

ABM-FM-6541 20 mm - 25 mm 4 mm - 6 mm 65 - 70 Pcs. 3 H.P.

BLIND (POP) RIVET ASSEMBLING MACHINES (Automatic, High Speed)

FEATURES

Latest improved design for mass production and lower maintenance cost.

Machines are fitted with two hoppers, one feeds the rivets and second feeds the nails.

The function of the machine is to fit the nails into the rivets.

SPECIFICATION

Item Code No. Length Diameter Production

Per Minute Motor H.P.

ABM-FM-6550 12 mm - 20 mm 2.5 mm - 4 mm 120 - 130 Pcs. 3 H.P.

ABM-FM-6551 20 mm - 25 mm 4 mm - 6 mm 100 - 120 Pcs. 3 H.P.

WIRE NAIL MAKING MACHINES (Automatic, High Speed)

For Pop Rivet / Blind Rivet)

FEATURES

CONSTRUCTION

ABM TOOLS Panel Pin & Wire Nails making machines crank type are made from high grade castings and steel. Machines ensure perfect sturdy construction and long life.

DRIVE

Three shafts design has been adopted to ensure efficient smooth working. The main crank is direct operated by motor. The side shafts are driven by four bevel gears, which operate cutting tools. The separate shafts for cutting ensure correct adjustment of tools.

BEARING

Main crank & side shafts are fitted with special gun metal Bushes to ensure long life. All the Bushes & Lubricating Points are provided with cup type oil reservoirs.

WORKING OF MACHINE

The wire end from coil passes through straightening rollers and fed intermittently in the gripping dies, which close firmly allowing heading punch to press the head of the nails, then grip loosened and required length of the nail is fed constantly, where it is cut by cutting tools leaving ample stock for the head of the next nail. Thus ready nail is ejected by the ejector. The operations are repeated in each revolution.

WIRE FEED

The wire feed is obtained from main crank shaft. The desired length of nail is easy to set by adjustment bolt.

ACCESSORIES FOR THE PLANT

Grinding Machine, Polishing Drum and Spare Dies, etc.

SPECIFICATION

Item Code No. ABM-FM-6572 ABM-FM-6573

Length of Nail 1/2" to 2"

12 to 50 mm) 3/4" to 3"

20 to 75 mm)

Thickness of Wire Gauge 1.6 to 2.6 mm

16 to 12 SWG) 2 to 3.7 mm

14 to 9 SWG)

Production Per Minute 300 to 350 Pcs. 225 to 275 Pcs.

Motor Required 2 H.P. x 1440 R.P.M. 3 H.P. x 1440 R.P.M.

Net Weight of Machine 500 Kg. 850 Kg.

Gross Weight of Machine 650 Kg. 1050 Kg.

Case Size 36" x 37" x 37" 47" x 56" x 42"

a) Automatic High Speed Double Stroke Cold Heading Machines

b) Automatic Blind (Pop) Rivet Assembling Machines

c) Automatic Wire Nail Making Machines (For Blind / Pop Rivet)

DOUBLE STROKE COLD HEADING MACHINES (Automatic, High Speed)

FEATURES

These cold heading machines are fully automatic and easy to operate with little training, fitted with Solid Die to produce blank for Bolts, Screws, Rivets and other similar components. Cut off and knock out mechanism have safely devices that will stop any major accident if any abnormal function occurs in machines.

A positive knock out provision had been made on the 1st and 2nd punches to eliminate the possibility of parts sticking to these punches during the operations. The maximum parts of the machines are ground and all the Cames and Rollers from H.C.H.C. ( Hardened & Ground ).

On some extra charges machines will be equipped with Pneumatic Clutch & Automatic Centralized Lubrications systems which provides sufficient quantity lubricating to all bearing surface.

SPECIFICATION

Item Code No. Length Diameter Production

Per Minute Motor H.P.

ABM-FM-6540 12 mm - 20 mm 2.5 mm - 4 mm 70 - 80 Pcs. 2 H.P.

ABM-FM-6541 20 mm - 25 mm 4 mm - 6 mm 65 - 70 Pcs. 3 H.P.

BLIND (POP) RIVET ASSEMBLING MACHINES (Automatic, High Speed)

FEATURES

Latest improved design for mass production and lower maintenance cost.

Machines are fitted with two hoppers, one feeds the rivets and second feeds the nails.

The function of the machine is to fit the nails into the rivets.

SPECIFICATION

Item Code No. Length Diameter Production

Per Minute Motor H.P.

ABM-FM-6550 12 mm - 20 mm 2.5 mm - 4 mm 120 - 130 Pcs. 3 H.P.

ABM-FM-6551 20 mm - 25 mm 4 mm - 6 mm 100 - 120 Pcs. 3 H.P.

WIRE NAIL MAKING MACHINES (Automatic, High Speed)

For Pop Rivet / Blind Rivet)

FEATURES

CONSTRUCTION

ABM TOOLS Panel Pin & Wire Nails making machines crank type are made from high grade castings and steel. Machines ensure perfect sturdy construction and long life.

DRIVE

Three shafts design has been adopted to ensure efficient smooth working. The main crank is direct operated by motor. The side shafts are driven by four bevel gears, which operate cutting tools. The separate shafts for cutting ensure correct adjustment of tools.

BEARING

Main crank & side shafts are fitted with special gun metal Bushes to ensure long life. All the Bushes & Lubricating Points are provided with cup type oil reservoirs.

WORKING OF MACHINE

The wire end from coil passes through straightening rollers and fed intermittently in the gripping dies, which close firmly allowing heading punch to press the head of the nails, then grip loosened and required length of the nail is fed constantly, where it is cut by cutting tools leaving ample stock for the head of the next nail. Thus ready nail is ejected by the ejector. The operations are repeated in each revolution.

WIRE FEED

The wire feed is obtained from main crank shaft. The desired length of nail is easy to set by adjustment bolt.

ACCESSORIES FOR THE PLANT

Grinding Machine, Polishing Drum and Spare Dies, etc.

SPECIFICATION

Item Code No. ABM-FM-6572 ABM-FM-6573

Length of Nail 1/2" to 2"

12 to 50 mm) 3/4" to 3"

20 to 75 mm)

Thickness of Wire Gauge 1.6 to 2.6 mm

16 to 12 SWG) 2 to 3.7 mm

14 to 9 SWG)

Production Per Minute 300 to 350 Pcs. 225 to 275 Pcs.

Motor Required 2 H.P. x 1440 R.P.M. 3 H.P. x 1440 R.P.M.

Net Weight of Machine 500 Kg. 850 Kg.

Gross Weight of Machine 650 Kg. 1050 Kg.

Case Size 36" x 37" x 37" 47" x 56" x 42"