Report the ad

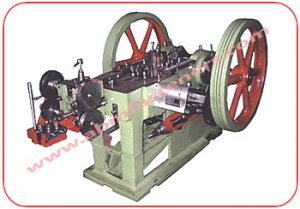

Bolt making plant - Delhi

Monday, 9 April, 2012

Item details

City:

Delhi

Offer type:

Sell

Item description

BOLT PLANT (Automatic Bolt Making Plant)

a) Automatic High Speed Double Stroke Cold Heading Machines

b) Automatic Bolt Head Trimming and Shank Reducing Machines

c) Automatic Thread Rolling Machines (High Speed)

DOUBLE STROKE COLD HEADING MACHINES (Automatic, High Speed)

Solid Die

FEATURES

These cold heading machines are fully automatic and easy to operate with little training, fitted with Solid Die to produce blank for Bolts, Screws, Rivets and other similar components. Cut off and knock out mechanism have safely devices that will stop any major accident if any abnormal function occurs in machines.

A positive knock out provision had been made on the 1st and 2nd punches to eliminate the possibility of parts sticking to these punches during the operations. The maximum parts of the machines are ground and all the Cames and Rollers from H.C.H.C. ( Hardened & Ground ).

On some extra charges machines will be equipped with Pneumatic Clutch & Automatic Centralized Lubrications systems which provides sufficient quantity lubricating to all bearing surface.

SPECIFICATION

Item Code No. Length of Bolt Dia. of Bolt Production

Per Minute Motor H.P.

R.P.M.

ABM-FM-6410 2" (12 mm - 50 mm) 1/4" (3 mm - 6 mm) 90 - 95 Pcs. 5 x 960

ABM-FM-6411 2-1/2" (20 mm - 65 mm) 5/16" (6 mm - 8 mm) 80 - 85 Pcs. 7.5 x 960

ABM-FM-6412 3" (20 mm - 75 mm) 3/8" (6 mm - 10 mm) 70 - 75 Pcs. 10 x 960

ABM-FM-6413 4" (25 mm - 100 mm) 1/2" (8 mm - 12 mm) 60 - 65 Pcs. 20 x 960

ABM-FM-6414 5" (35 mm - 125 mm) 5/8" (10 mm - 16 mm) 50 - 55 Pcs. 30 x 960

ABM-FM-6415 6" (50 mm - 150 mm) 3/4" (12 mm - 20 mm) 35 - 40 Pcs. 40 x 960

BOLT HEAD TRIMMING AND SHANK REDUCING MACHINES

Automatic, High Speed)

FEATURES

ABM Tools Automatic Bolt head Trimmers are extra exclusive in their transport system. One of the Special features is that bolts with extreme short shank length can be transported without any difficulty. It makes ABM TOOLS Trimmer the fastest in the market.

The simplicity of the tooling increases the efficiency considerably and cuts down on set up time.

The machine is well known ABM TOOLS quality which stands for excellent workmanship and superior design.

ESSENTIAL FEATURES

Machine design is very simple. All working parts & gears are enclosed as possible. Speed can be changed by motor pulley. Automatic feed with efficient drum type hopper of high capacity.

Bolts are transferred by finger from feed rails to trimming die. All adjustments are easy operated and simple. Vibrator Hopper for odd components (optional)

Fastest machine on the Market

Sophisticated Transport System

Rugged design

One operator for upto 4 machines

Fine Stroke adjustment

SPECIFICATION

Item Code No. Length of Bolt Dia. of Bolt Production

Per Minute Motor H.P.

R.P.M.

ABM-FM-6420 2" (12 mm - 50 mm) 1/4" (3 mm - 6 mm) 90 - 95 Pcs. 3 x 1400

ABM-FM-6421 2-1/2" (20 mm - 65 mm) 5/16" (6 mm - 8 mm) 80 - 85 Pcs. 5 x 1400

ABM-FM-6422 3" (20 mm - 75 mm) 3/8" (6 mm - 10 mm) 70 - 75 Pcs. 7.5 x 1400

ABM-FM-6423 4" (25 mm - 100 mm) 1/2" (8 mm - 12 mm) 60 - 65 Pcs. 10 x 1400

ABM-FM-6424 5" (35 mm - 125 mm) 5/8" (10 mm - 16 mm) 50 - 55 Pcs. 15 x 1400

ABM-FM-6425 6" (50 mm - 150 mm) 3/4" (12 mm - 20 mm) 35 - 40 Pcs. 25 x 1400

THREAD ROLLING MACHINES (Automatic, High Speed)

FEATURES

These machines are designed for mass production and lowest maintenance cost.

Suitable for threading bolts, automobile parts and other similar components.

Two flats dies used in these machines, which easily fitted and adjusted.

SPECIFICATION

Item Code No. Length of Bolt Dia. of Bolt Production

Per Minute Motor H.P.

R.P.M.

ABM-FM-6430 2" (12 mm - 50 mm) 1/4" (3 mm - 6 mm) 90 - 95 Pcs. 3 x 1400

ABM-FM-6431 2-1/2" (20 mm - 65 mm) 5/16" (6 mm - 8 mm) 80 - 85 Pcs. 5 x 1400

ABM-FM-6432 3" (20 mm - 75 mm) 3/8" (6 mm - 10 mm) 70 - 75 Pcs. 7.5 x 1400

ABM-FM-6433 4" (25 mm - 100 mm) 1/2" (8 mm - 12 mm) 60 - 65 Pcs. 10 x 1400

ABM-FM-6434 5" (35 mm - 125 mm) 5/8" (10 mm - 16 mm) 50 - 55 Pcs. 15 x 1400

ABM-FM-6435 6" (50 mm - 150 mm) 3/4" (12 mm - 20 mm) 35 - 40 Pcs. 25 x 1400

a) Automatic High Speed Double Stroke Cold Heading Machines

b) Automatic Bolt Head Trimming and Shank Reducing Machines

c) Automatic Thread Rolling Machines (High Speed)

DOUBLE STROKE COLD HEADING MACHINES (Automatic, High Speed)

Solid Die

FEATURES

These cold heading machines are fully automatic and easy to operate with little training, fitted with Solid Die to produce blank for Bolts, Screws, Rivets and other similar components. Cut off and knock out mechanism have safely devices that will stop any major accident if any abnormal function occurs in machines.

A positive knock out provision had been made on the 1st and 2nd punches to eliminate the possibility of parts sticking to these punches during the operations. The maximum parts of the machines are ground and all the Cames and Rollers from H.C.H.C. ( Hardened & Ground ).

On some extra charges machines will be equipped with Pneumatic Clutch & Automatic Centralized Lubrications systems which provides sufficient quantity lubricating to all bearing surface.

SPECIFICATION

Item Code No. Length of Bolt Dia. of Bolt Production

Per Minute Motor H.P.

R.P.M.

ABM-FM-6410 2" (12 mm - 50 mm) 1/4" (3 mm - 6 mm) 90 - 95 Pcs. 5 x 960

ABM-FM-6411 2-1/2" (20 mm - 65 mm) 5/16" (6 mm - 8 mm) 80 - 85 Pcs. 7.5 x 960

ABM-FM-6412 3" (20 mm - 75 mm) 3/8" (6 mm - 10 mm) 70 - 75 Pcs. 10 x 960

ABM-FM-6413 4" (25 mm - 100 mm) 1/2" (8 mm - 12 mm) 60 - 65 Pcs. 20 x 960

ABM-FM-6414 5" (35 mm - 125 mm) 5/8" (10 mm - 16 mm) 50 - 55 Pcs. 30 x 960

ABM-FM-6415 6" (50 mm - 150 mm) 3/4" (12 mm - 20 mm) 35 - 40 Pcs. 40 x 960

BOLT HEAD TRIMMING AND SHANK REDUCING MACHINES

Automatic, High Speed)

FEATURES

ABM Tools Automatic Bolt head Trimmers are extra exclusive in their transport system. One of the Special features is that bolts with extreme short shank length can be transported without any difficulty. It makes ABM TOOLS Trimmer the fastest in the market.

The simplicity of the tooling increases the efficiency considerably and cuts down on set up time.

The machine is well known ABM TOOLS quality which stands for excellent workmanship and superior design.

ESSENTIAL FEATURES

Machine design is very simple. All working parts & gears are enclosed as possible. Speed can be changed by motor pulley. Automatic feed with efficient drum type hopper of high capacity.

Bolts are transferred by finger from feed rails to trimming die. All adjustments are easy operated and simple. Vibrator Hopper for odd components (optional)

Fastest machine on the Market

Sophisticated Transport System

Rugged design

One operator for upto 4 machines

Fine Stroke adjustment

SPECIFICATION

Item Code No. Length of Bolt Dia. of Bolt Production

Per Minute Motor H.P.

R.P.M.

ABM-FM-6420 2" (12 mm - 50 mm) 1/4" (3 mm - 6 mm) 90 - 95 Pcs. 3 x 1400

ABM-FM-6421 2-1/2" (20 mm - 65 mm) 5/16" (6 mm - 8 mm) 80 - 85 Pcs. 5 x 1400

ABM-FM-6422 3" (20 mm - 75 mm) 3/8" (6 mm - 10 mm) 70 - 75 Pcs. 7.5 x 1400

ABM-FM-6423 4" (25 mm - 100 mm) 1/2" (8 mm - 12 mm) 60 - 65 Pcs. 10 x 1400

ABM-FM-6424 5" (35 mm - 125 mm) 5/8" (10 mm - 16 mm) 50 - 55 Pcs. 15 x 1400

ABM-FM-6425 6" (50 mm - 150 mm) 3/4" (12 mm - 20 mm) 35 - 40 Pcs. 25 x 1400

THREAD ROLLING MACHINES (Automatic, High Speed)

FEATURES

These machines are designed for mass production and lowest maintenance cost.

Suitable for threading bolts, automobile parts and other similar components.

Two flats dies used in these machines, which easily fitted and adjusted.

SPECIFICATION

Item Code No. Length of Bolt Dia. of Bolt Production

Per Minute Motor H.P.

R.P.M.

ABM-FM-6430 2" (12 mm - 50 mm) 1/4" (3 mm - 6 mm) 90 - 95 Pcs. 3 x 1400

ABM-FM-6431 2-1/2" (20 mm - 65 mm) 5/16" (6 mm - 8 mm) 80 - 85 Pcs. 5 x 1400

ABM-FM-6432 3" (20 mm - 75 mm) 3/8" (6 mm - 10 mm) 70 - 75 Pcs. 7.5 x 1400

ABM-FM-6433 4" (25 mm - 100 mm) 1/2" (8 mm - 12 mm) 60 - 65 Pcs. 10 x 1400

ABM-FM-6434 5" (35 mm - 125 mm) 5/8" (10 mm - 16 mm) 50 - 55 Pcs. 15 x 1400

ABM-FM-6435 6" (50 mm - 150 mm) 3/4" (12 mm - 20 mm) 35 - 40 Pcs. 25 x 1400